UMR7178

Institut pluridisciplinaire Hubert Curien - IPHC

L’IPHC, unité mixte de recherche sous cotutelle du CNRS et de l’Université de Strasbourg (UMR7178), est un exemple de réussite de la pluridisciplinarité où des équipes de recherche de cultures scientifiques différentes (écologie, physiologie et éthologie, chimie et physique subatomique) développent des programmes pluridisciplinaires de très haut niveau avec pour socle l’instrumentation scientifique.

Nos départements de recherche

Les Actualités

Voir toutes les actualités

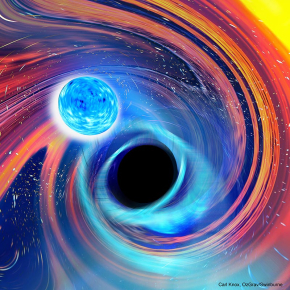

Un signal d’ondes gravitationnelles rebat les cartes des masses des objets célestes

Journée LabEx IRON : 13 ans de succès !

Le LabEx IRON, dont l'IPHC est partenaire, organise sa journée de clôture, qui sera l’occasion de dresser un bilan de 13 années d’existence du réseau, de faire le point sur les avancées scientifiques majeures obtenues pendant cette période et de se projeter vers l’avenir.

Carnets de science | Fascinantes cultures des macaques du Japon

Dans le numéro d'Automne / Hiver 2023 de la revue Carnets de science, Cédric Sueur raconte, au travers d'un Carnet de mission, ses recherches en éthologie sur la macaque du Japon.

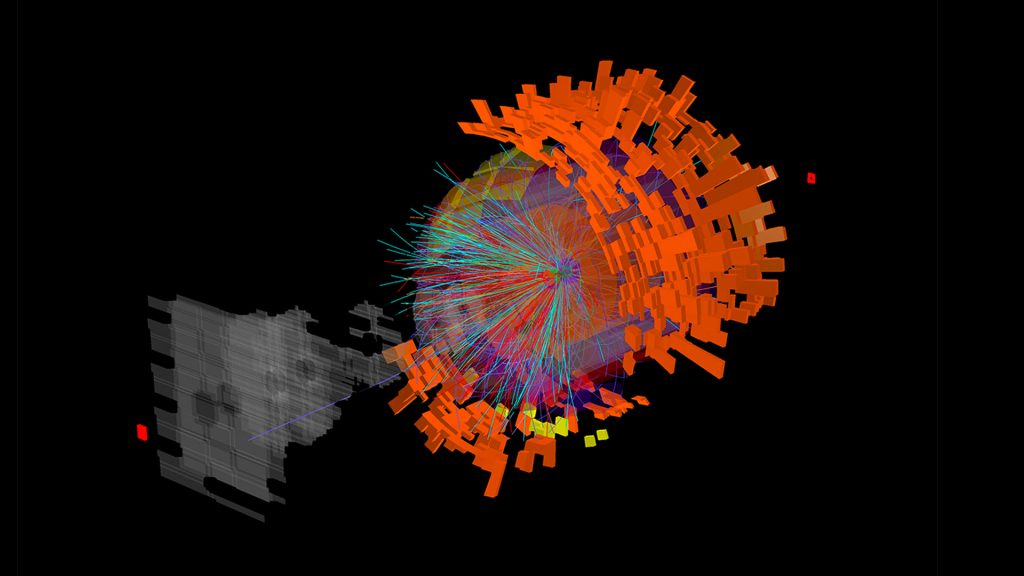

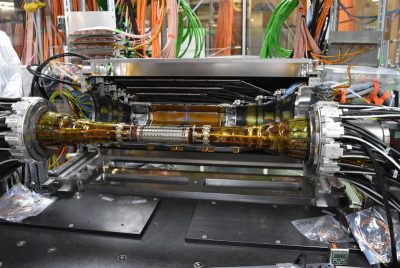

Dans les starting-blocks pour le redémarrage de BELLE-II

Après un arrêt technique d'un an et demi, l'expérience Belle II, située à Tsukuba au Japon, est prête à reprendre des données. L'analyse des données de la campagne 2019-2022 effectuée durant cet arrêt technique a révélé les signes de la désintégration du méson B →K+ ν anti-ν, un des points forts des grandes conférences internationales de l’été dans la discipline.

Penser moins pour manger plus !

Une étude parue dans Mammalian Biology révèle que les souris rayées africaines ont un cerveau 10% plus petit en été, lors de la saison sèche où la nourriture se fait rare.

Disparition de Berrie Giebels, Directeur Adjoint de l’IN2P3

Notre laboratoire est profondément attristé par le décès de Berrie Giebels, physicien au LLR et Directeur Adjoint de l'IN2P3.

Suivez-nous

Prochains évènements

Voir l’agenda19 avril 2024

Séminaire Louis Lalanne (IPHC)

https://indico.in2p3.fr/event/32408/

19 avril 2024

IDROGEN

Speakers: Daniel Charlet (IJCLAB) https://indico.in2p3.fr/event/32744/